|

As well as fixed resistors it is often necessary to include a variable resistor in a circuit to provide some means of adjustment. This may be due to a calibration requirement where a circuit needs to be adjusted to compensate for component tolerances or simply a user adjustment such as the volume control on an amplifier.

The variable resistor has 3 terminals and is usually constructed as a resistive track with a terminal at each end and a movable terminal known as the wiper which makes contact with the track. The exact mechanical construction and materials used depends upon the application and environment in which it is going to be used.

Variable resistors may often be referred to as potentiometers or rheostats. A brief explanation of each term follows:

Rheostat This term is usually applied to a variable resistor which is used to vary the current flow in a circuit. This method only uses one end terminal and the wiper terminal of the variable resistor. The unused end terminal is often connected to the wiper terminal to prevent stray signals from being picked up and introduced into the circuit.

Potentiometer This uses all 3 connections of the variable resistor and is used to give voltage adjustment. The voltage on the wiper terminal may be varied between the voltages at either end of the track of the resistor.

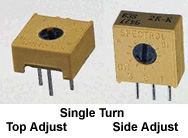

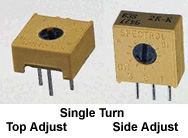

Variable resistors used to set internal parameters on circuits are generally referred to as presets or trimmers. They are usually small in construction and require a screwdriver for adjustment. There are many different package styles with the screwdriver adjustment slot in different places for either top access or front access.

As well as the basic rotary type, there is also the multi-turn type. This type propels the wiper terminal along the track using a screw thread. This can give a much finer range of adjustment and may be used where a precision setting is required. As well as the basic rotary type, there is also the multi-turn type. This type propels the wiper terminal along the track using a screw thread. This can give a much finer range of adjustment and may be used where a precision setting is required.

|

As well as the basic rotary type, there is also the multi-turn type. This type propels the wiper terminal along the track using a screw thread. This can give a much finer range of adjustment and may be used where a precision setting is required.

As well as the basic rotary type, there is also the multi-turn type. This type propels the wiper terminal along the track using a screw thread. This can give a much finer range of adjustment and may be used where a precision setting is required. Variable resistors are also used as the external controls on many pieces of equipment, quite often as a volume control or something similar. They are usually divided into two basic types, rotary and slider.As the name suggests, the rotary type is basically a larger version of the single turn presets shown above. The device usually has a metal or plastic control shaft onto which a suitable control knob is fixed. Many types also have a threaded collar for fixing through the front panel of the equipment.

Variable resistors are also used as the external controls on many pieces of equipment, quite often as a volume control or something similar. They are usually divided into two basic types, rotary and slider.As the name suggests, the rotary type is basically a larger version of the single turn presets shown above. The device usually has a metal or plastic control shaft onto which a suitable control knob is fixed. Many types also have a threaded collar for fixing through the front panel of the equipment.  In some cases, such as stereo equipment, it may be necessary to adjust two levels simultaneously. In this case a dual gang potentiometer is used. This is basically two devices attached to the same control shaft.

In some cases, such as stereo equipment, it may be necessary to adjust two levels simultaneously. In this case a dual gang potentiometer is used. This is basically two devices attached to the same control shaft.